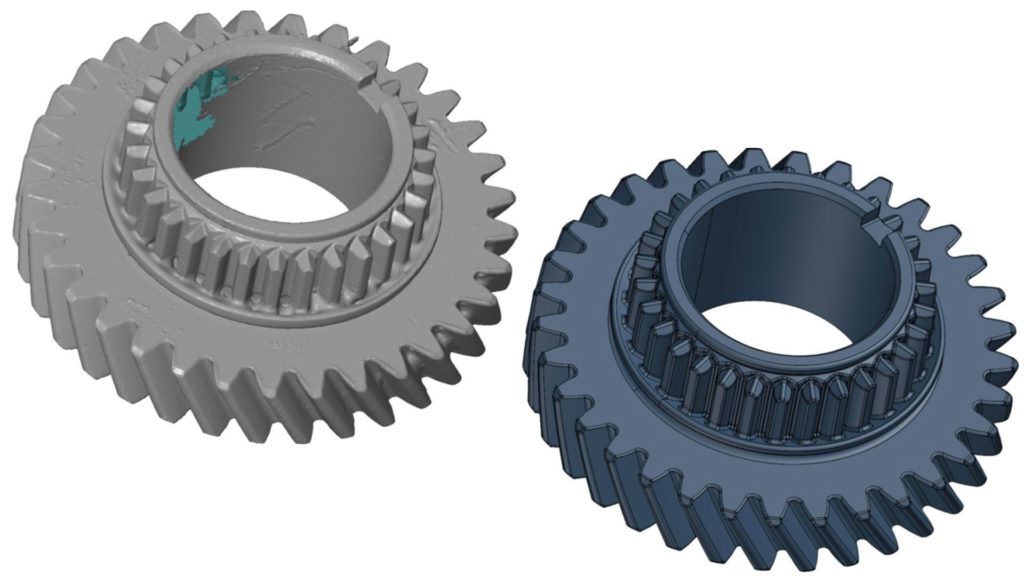

Example 1: Deviation Analysis for Quality Control in Production

If a company manufactures metal gears, every day, the factory produces 1000s of gears. Six gears

are taken at random from the production line, and then 3D-scanned. From the time the gear is

initially designed, there is a CAD model. The CAD model is a 3D file with all dimensions of a perfect

gear. This CAD model is compared with the 3D scans from the production line. This is a “nominal

actual comparison”. It is a deviation analysis that shows how much the gears from production

deviate from a perfect gear. Based on this analysis, the engineers can optimize the gear production

machine to improve manufacturing quality.

Example 2: Deviation Analysis for Quality Control in Reverse Engineering

A part is first 3D-scanned, then a reverse-engineered model is created from this 3d scan. However,

the reverse engineering process can only approximate the 3D scan. The differences between the 3D

scan and the reverse engineering are then analyzed and visualized with a deviation analysis and a

false color comparison.

Deviation Analysis in Four Steps

- Import of the nominal data (e.g., CAD file of the perfect gear).

- Import of the actual data (e.g., 3D scan of the manufactured gear).

- Both data sets are superimposed in the analysis software (GOM Inspect)

- The data sets are compared, and a deviation analysis report is created. The differences are

- visualized with a false color comparison.

Deviation Analysis Report

Two 3D models are superimposed using the analysis software “GOM Inspect”. The differences

between the two data sets are displayed in color. Different colors correspond to positive and

negative deviations. On the right side of the report, there is a legend showing a color gradient. Red

means that the actual data is above the nominal data. Blue means that the actual data is below the

nominal data.

Free software GOM Inspect for creating a deviation analysis or nominal actual comparison report

The best and free software to create a deviation analysis or nominal actual comparison report is

GOM inspect. GOM is a company that builds predominantly 3D Scanners but also makes great

software.

Do you require a deviation analysis with your reverse engineering project?

Holocreators offers professional 3D-scanning and reverse engineering services. For quality

assurance, and so that the customer can check how far our reverse engineering deviates from the

original 3D scan, we always deliver a deviation analysis. We would be happy to assist you with your

project. Please call us at +49 40 481133 or send an email info@holocreators.com