3D Scans with CT for 95 EUR – Here’s How We Do It

We have developed a solution to bring the cost of 3D CT scanning down to just 95 EUR per part while maintaining excellent 3D scan quality. We do this by pooling the parts from multiple customers and scanning them all at once.

In this article, we’ll show you exactly how the process works and what to expect at each stage.

Preparing for 3D CT Scanning

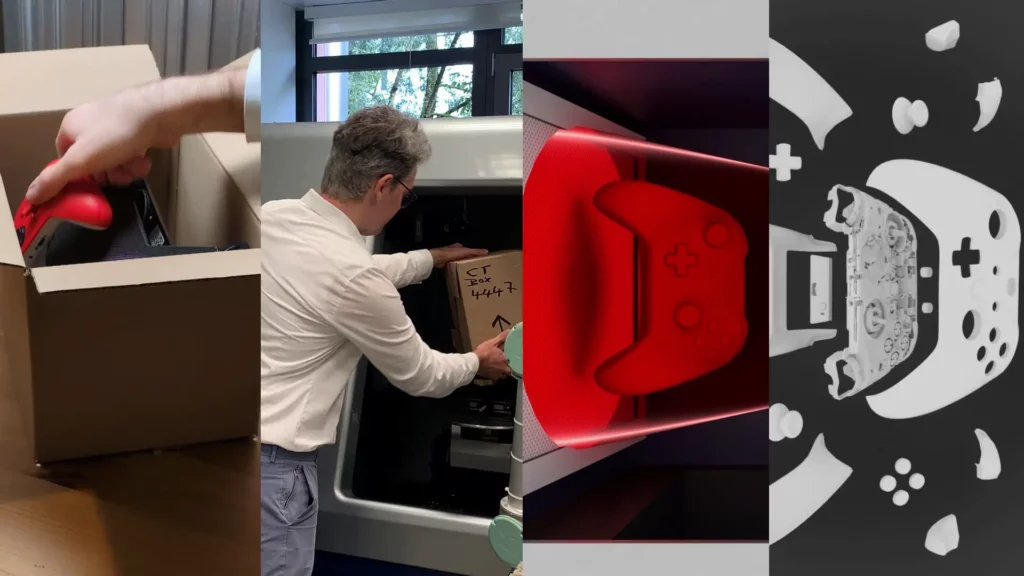

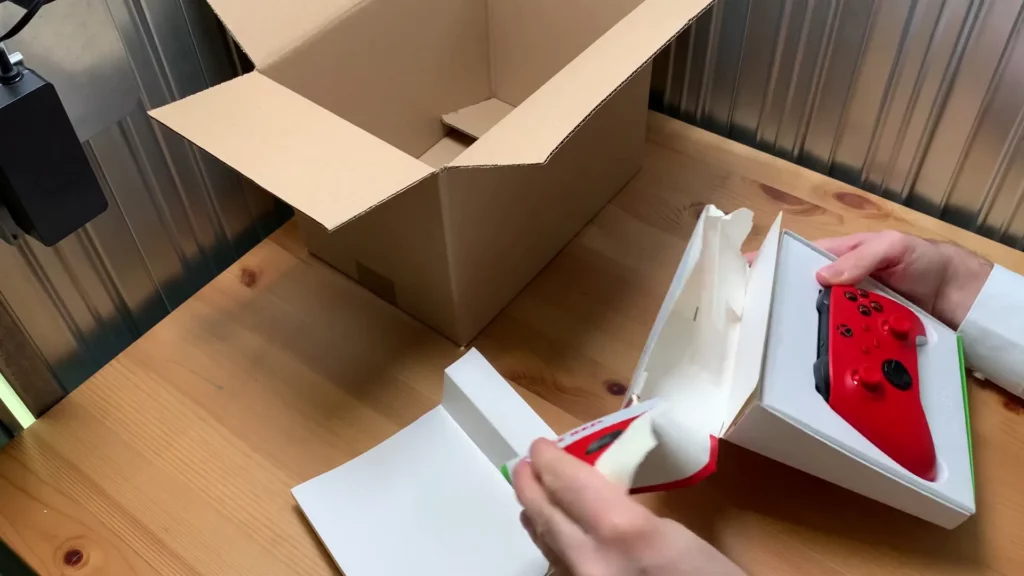

To demonstrate our cost-saving approach, we’ll use this new game controller as an example. Let’s start by unboxing it and getting it ready for the CT scan.

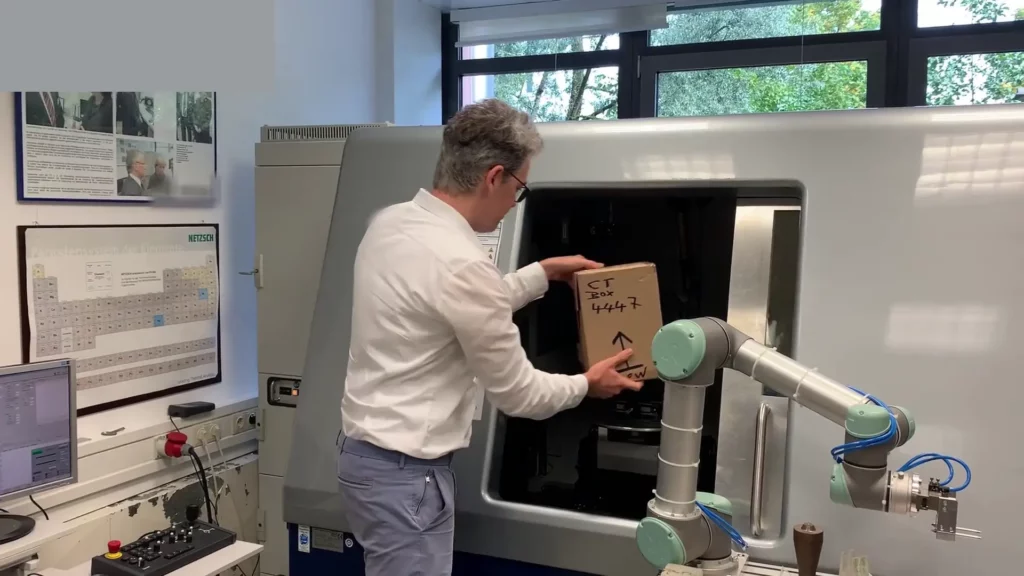

To get an accurate 3D CT scan, the object needs to fit within the fixed scan volume. We’ll be using a 25 by 25 by 30 centimeter cardboard box, which is just the right size to fit the game controller perfectly.

Now it’s time to place the box inside the 3D CT scanner. It’s a powerful, high-tech machine that uses X-rays to peer inside objects and create detailed 3D images. Its solid door shuts tight, locking everything in for a safe and to protect the operator from the x-ray radiation.

Inside the CT Scanner

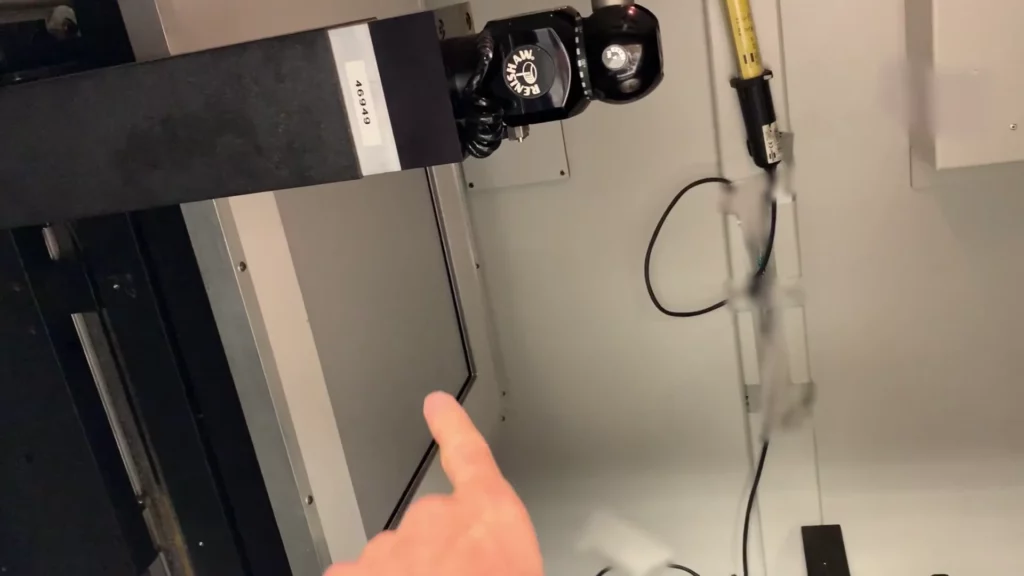

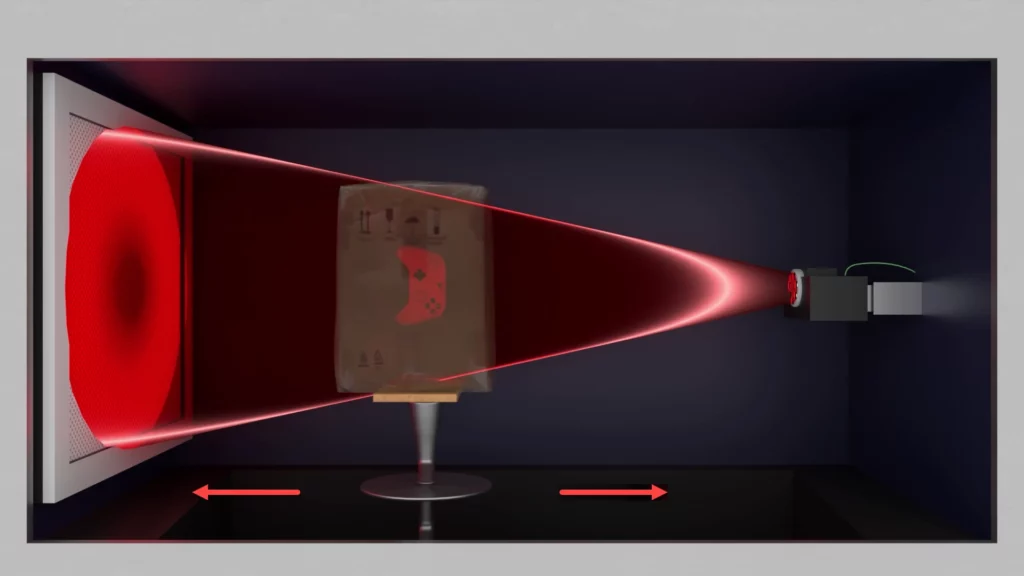

Let’s explore what’s happening inside the CT scanner. On the right side, we have the X-ray emitter. It sends out a powerful beam of X-rays that passes through the object we’re scanning.

On the opposite side sits the detector, a large sensor that captures the X-rays after they’ve passed through the object.

Together, these two components allow us to see inside solid parts and create highly detailed 3D scans.

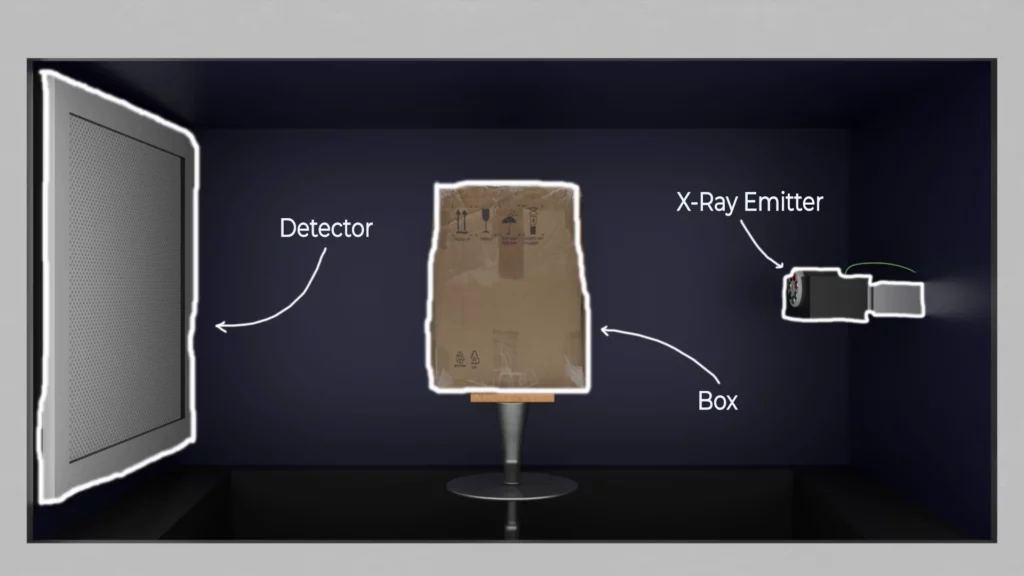

To make things clearer, we’ve created this simple image. On the right, you see the X-ray emitter; in the center is our box; and on the left, the detector. While the box holds everything in place, it’s completely invisible to the CT scanner.

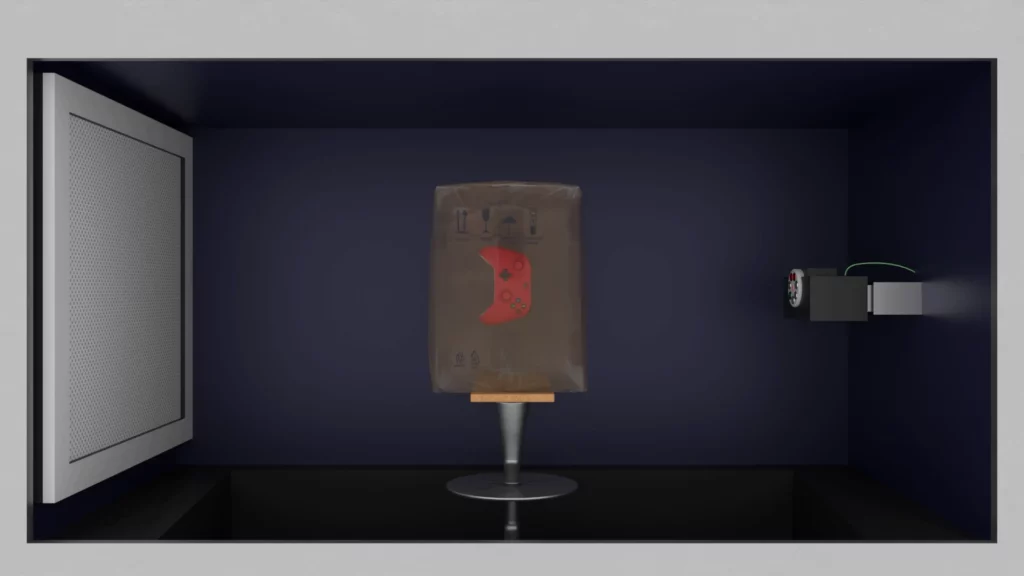

We’ve placed our game controller inside the box. The CT scan will capture every detail of the object inside, but the box itself will remain invisible.

Controlling the Resolution Through Placement

Once we power on the emitter, it emits a steady X-ray beam toward the detector. The beam’s spread stays fixed, but we can slide the box between the emitter and the detector.

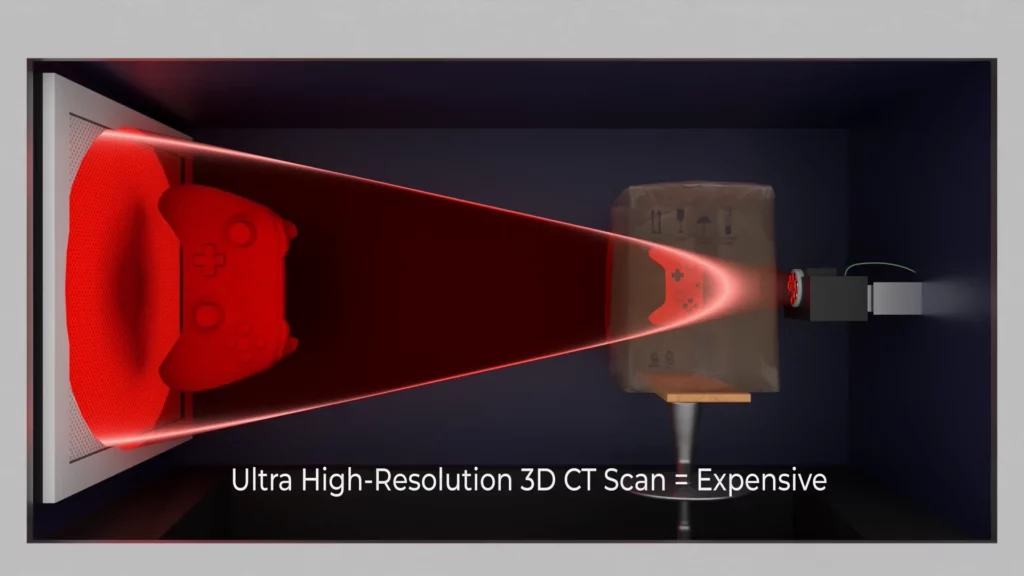

Since the game controller is relatively small, we can position it very close to the X-ray emitter. This gives us a large, detailed projection on the detector, that’s perfect for capturing an ultra-high-resolution 3D scan. Increasing the size of the projection on the detector enhances the resolution of the 3D scan.

The catch? A narrow beam means we can only scan one object at a time. While the detail is incredible, the 3D scan is expensive.

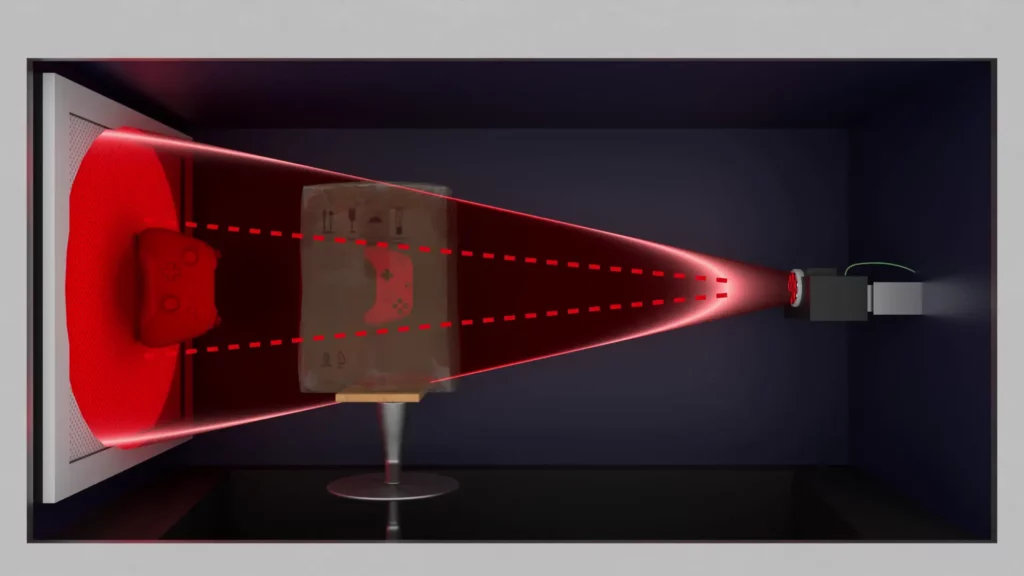

When we move the box farther from the emitter, the controller’s projection on the detector becomes smaller. That means we’ll get a bit less details but more space inside the 3D scan volume. And that’s where things get exciting – this extra space allows us to scan multiple parts in a single session. Thus lowering the price per 3D scan.

Lowering Costs with Multi-Part 3D Scans

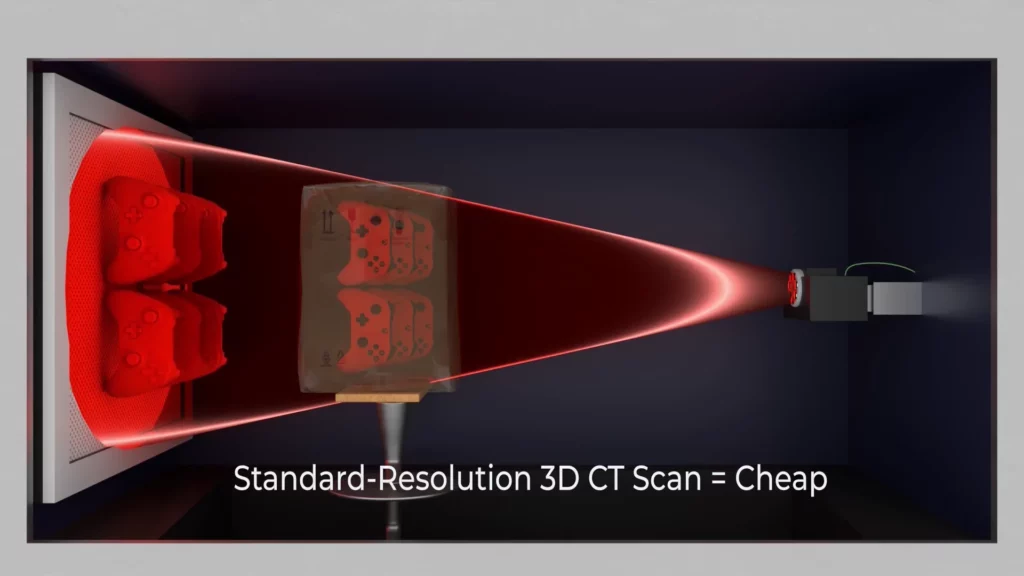

Now that the X-ray beam is fully expanded, we can fit multiple game controllers into the box at the same time.

Scanning multiple objects in a single session brings the cost down. The resolution also drops slightly, but the results are still excellent.

Conversion of 3D CT raw data into a 3D model (STL)

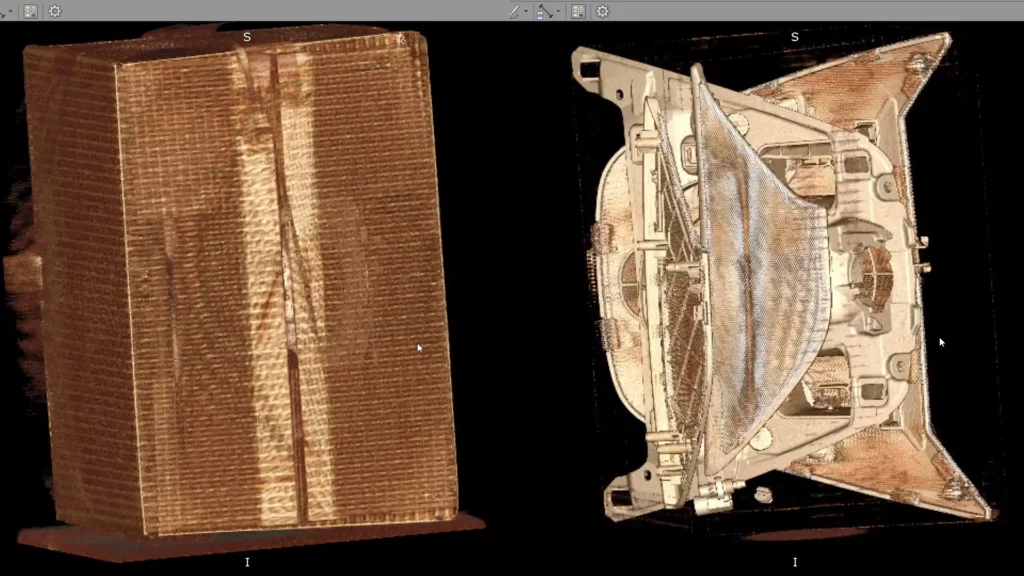

After the 3D CT scan is complete, we get a preview of the 3D CT raw data. Using specialized software, we can filter the scan to highlight different materials. At first, we only see the outer box, but with a few adjustments, the parts inside become visible.

In the final step, we export the 3D models as STL files. In this case we have created a detailed, exploded view of the game controller.

Affordable CT Scanning for Your Projects

By using this scanning technique, we make CT scanning more affordable without compromising on quality. If you’re working on a project and need precise 3D models, this 3D scanning method is for you.

We offer the 3D CT scan for 95 EUR per part. Would you like us to 3d scan one of your parts? Simply send it our way.

Holocreators provides scanning services and 3D scan to CAD conversion services (STL to STEP). We are dedicated to assisting you with your projects. Feel free to reach out to us at +49 40 481133 or via email at info@holocreators.com