A Closer Look at the Artec Space Spider

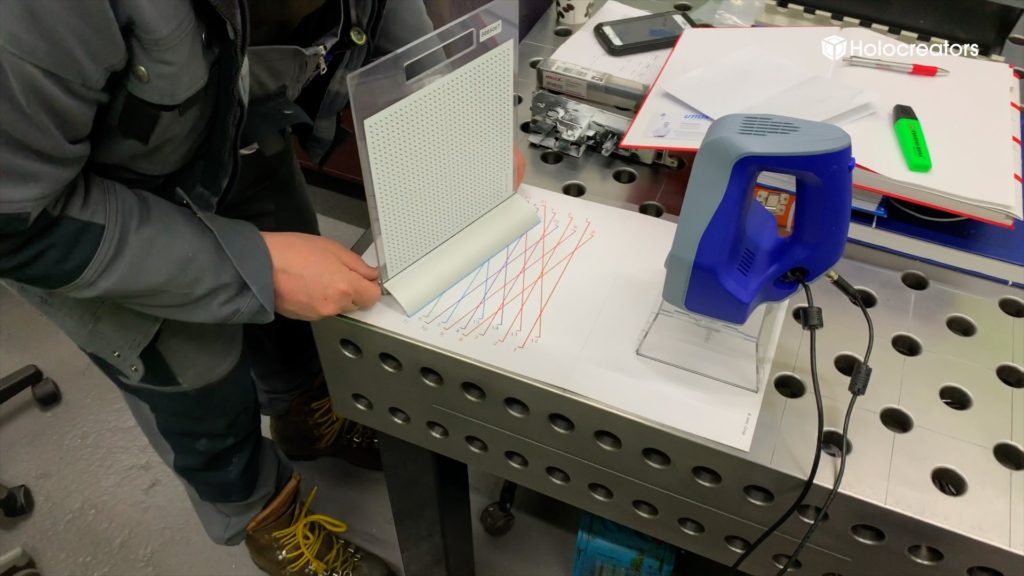

On the front right of the Artec Space Spider is the projector. It projects a blue-structured light

pattern onto the object to be scanned. The surface of the object curves this projected pattern .

Three cameras capture the curvature and distortion of the pattern and calculate the geometry of the

object. The color camera is installed in the center. Therefore, the light-emitting diodes are arranged

in a circle. During the scanning process, the camera records the color texture.

The 3D scanner must be connected to a power supply and a laptop during the scanning process. This

is done with two cables: one for power and one for the data transfer. There is also a rechargeable

battery, which makes the power cable redundant. The battery lasts for about three scans.

On the backside of the Artec Space Spider is a button—push forward for 3D scanning and backward

to stop the scan. The Space Spider has the weight and feel of a clothes iron. During the scanning

process, the Space Spider must be connected to a PC or laptop. It works with the software “Artec

Studio”. During the scanning process, you can see real-time capturing on the screen—so if there are

any errors, you can quickly correct and re-capture erroneous areas.

Possible Source Errors During 3D Scanning

When 3D scanning with the Artec Space Spider, 20 cm from the object is ideal. The software “Artec

Studio” displays the optimal distance on the connected laptop. The Space Spider has a measuring

field of view of about 10 cm. This means that for larger objects, the software combines several

partial scans in real-time. The 3D scanner does this by orientating itself on the previously scanned

section while you move around the object. With objects larger than 30 cm, this can lead to errors

because the software has problems combining images correctly.

Negative example: We wanted to record a motorcycle tank with the Artec Space Spider for a

customer. The tank totaled 60 cm in length. While we moved around the tank to 3D scan it, the

errors added up, resulting in an inaccurate 3D scan.

The Advantages of the Artec Space Spider

One big advantage of the Space Spider is its light weight and mobility. It is stored in a transport box

and is ready for use at the customer’s site in 2 minutes—after warming up. Unlike other 3D

scanners, it does not have to be recalibrated after each use, but for an accurate 3D scan, it is

recommended.

Additionally, the 3D scanner has different software settings with which the density of the point cloud

generated during 3D scanning can be modified. The denser the point cloud, the more accurate the

3D scan.

Besides the 3D model, the Artec Space Spider also creates color texture—either as a 4k or 8k

textured map. However, the color quality is not as good as a fine photogrammetric 3D Scan.

The Accuracy of the Artec Space Spider

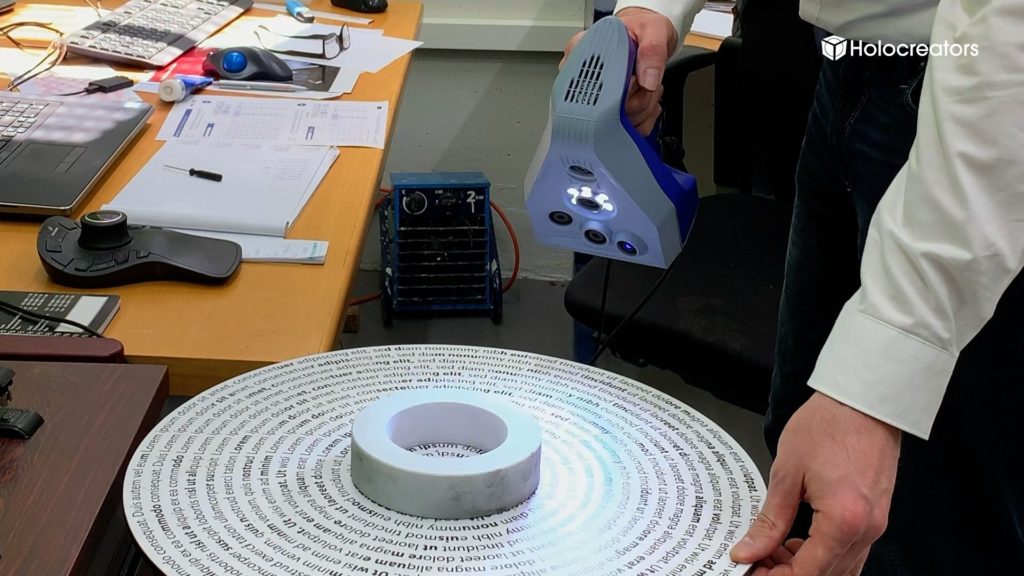

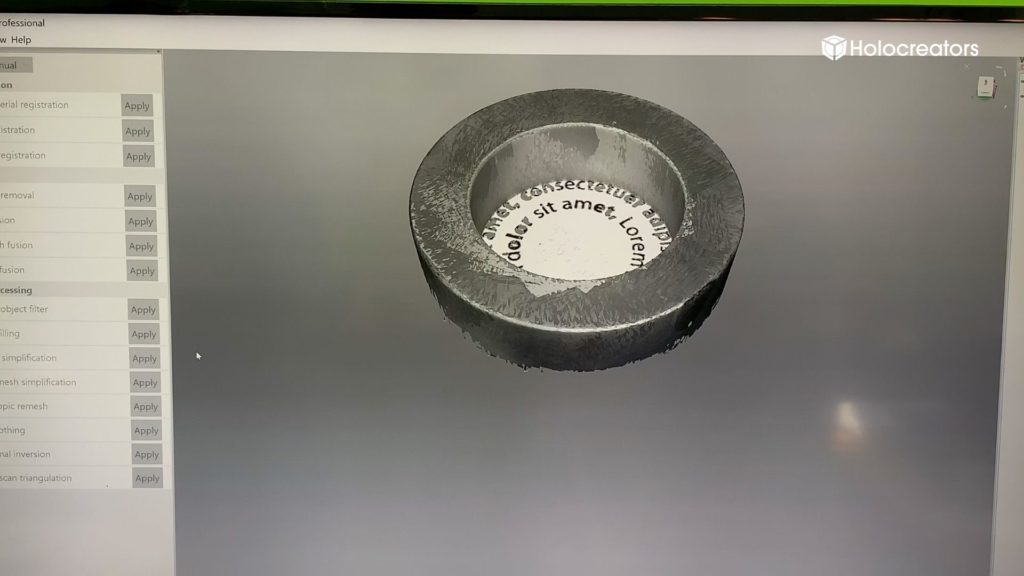

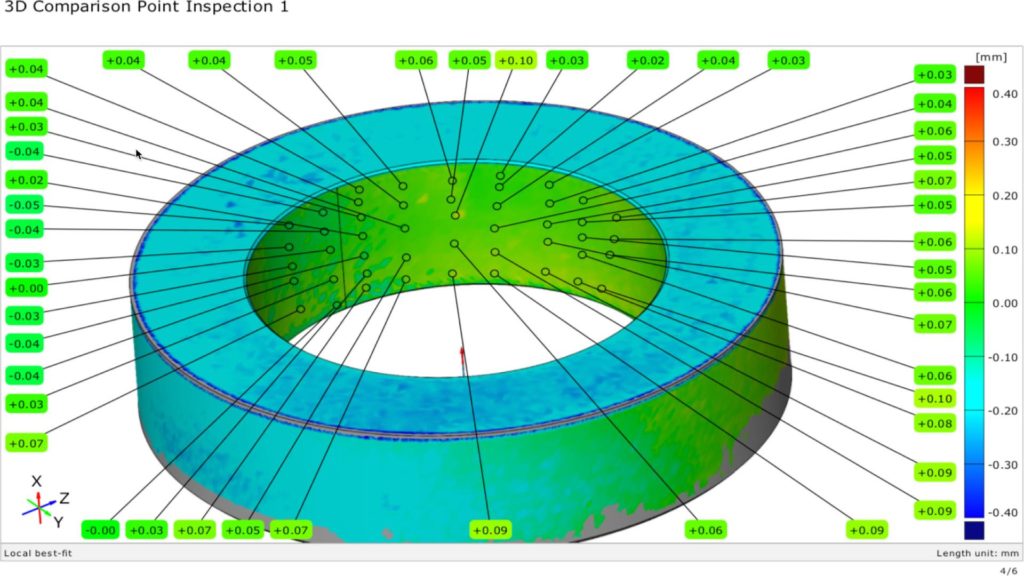

To test the accuracy, we 3D scanned a ring gauge for a micrometer. This ring gauge has a calibrated

inner diameter of 90 mm. We then compared the 3D scan with a CAD model of the ring gauge. This

deviation analysis (nominal actual comparison) resulted in the Artec Space Spider 3D scanner

providing accuracy within about +-0.05mm.

3D Project Files Available for Download

We have prepared the original 3D scan, the CAD model and the deviation analysis for you to

download:

- Original 3D scan with the Artec Space Spider of the ring gauge (STL)

- CAD Modell (nominal) of the ring gauge (STEP)

- Deviation analysis, nominal actual comparison of the CAD model and 3D scan (PDF)

- FreeCAD (free CAD software)

- Meshlab 3D viewer (free Software)

Conclusion

The Artec Space Spider has a good price/performance ratio. It is mobile and light and is a good entrylevel scanner for professionals. We use it to 3D scan for customers with smaller budgets who need

to balance cost and accuracy.

Do you need a 3D scan made with the Artec Space spider?

Holocreators offers professional 3D-scanning and reverse engineering services. If you need a 3D scan

made with the Artec Space Spider or would like help with any other 3D scanning project, we can help

you. Just give us a call at +49 40 481133 or send us an email: info@holocreators.com