How Does Selective Laser Melting Work?

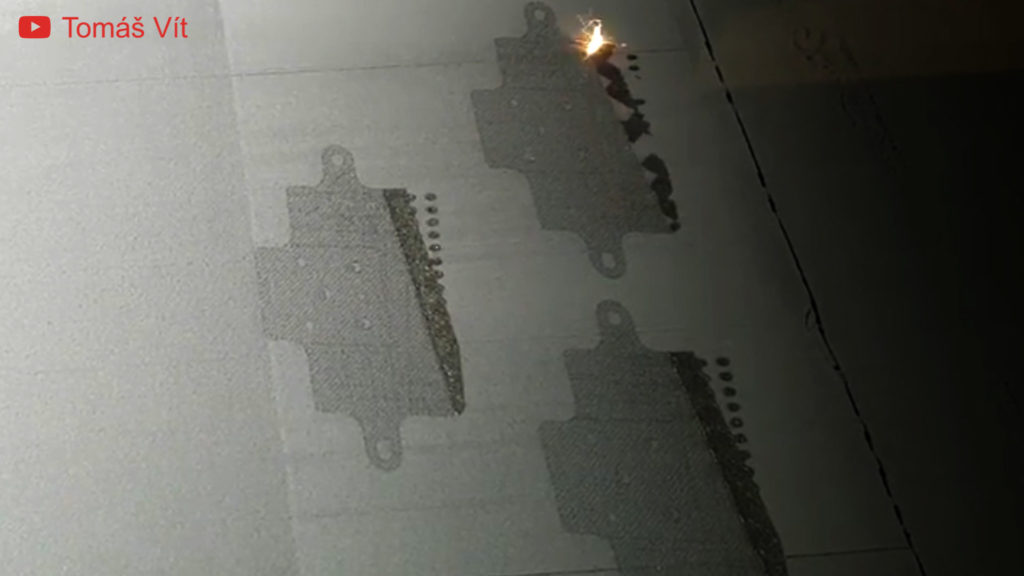

The process starts with a base plate. A scraper moves back and forth and spreads metal powder on

it. The laser then melts the powder only at the points where the object is to be made. At these

points, a solid metal part is created, while the loose powder remains. This process, known as

selective laser melting (SLM), is repeated layer by layer until the complete object is finished.

The metal powder plays a central role in selective laser melting (SLM). To produce a part, not only

must the correct powder be used, but the base plate must also be made of the same metal as the

part itself. The part is built up layer by layer. Each layer is only 0.03 mm thin. This means it can take

up to 30 to 40 hours to produce a large part using SLM. During this time, the machine melts

countless layers of metal powder.

Why Is a Supporting Structure Needed for 3D Metal Prints?

If the part to be printed has overhangs that cannot be supported by the powder inside the 3D

printer, then a supporting structure is required. As a rule of thumb, if the overhang is more than 45

degrees, a supporting structure must be added. This support structure holds the part during the 3D

printing process so that it does not sag or deform.

After the printing process, the remaining metal powder and the supporting structures must be

removed. Parts made with 3D metal printing have a rough surface. Holes or threads cannot be

printed directly but must be drilled separately, such as with a CNC milling machine.

Conclusion

Selective laser melting (SLM) is a metal 3D printing process. It can be used to create metal

components that are not possible with any other manufacturing process. In particular, complex

internal structures such as cooling channels can be integrated directly into the part. The costs for

metal 3D printing are very high compared to traditional manufacturing methods such as CNC milling.

For this reason, metal 3D printing has so far only been used in rapid prototyping or very small

production runs.

Do you want to 3D print a part in metal?

Holocreators offers professional 3D-scanning and reverse engineering services. We are also very

experienced with 3D printing, and we would happily advise you how to 3d print your part in metal. Please call us at +49 40 481133 or send an email info@holocreators.com