Fun fact: Vitronic is known in Germany for the production of radar systems for traffic surveillance—

they specialize in speed cameras.

The Vitronic Vitus is a 3D scanner that enables the fast and contactless capturing of 3D body scans.

Immediately after the 3D scanning process, a color 3D model can be exported. The Vitus is a

structured-light scanner that projects an infrared line pattern onto the person to be scanned. In

contrast to photogrammetry, structured-light scanning has the advantage of providing extremely

accurate measurements.

Differences Between Photogrammetry and Structured-light Scanning

Photogrammetry

In photogrammetry, we use about 70 cameras in a scan cabin, which trigger simultaneously. This

results in a photoset, that is subsequently calculated into a 3D model. Unfortunately, no direct

scaling of the 3D model is possible. Therefore, the person to be scanned must take a measuring stick

with him/her into the cabin to enable a subsequent scaling.

Structured-light Scanning

In structured-light scanning, a stripe pattern is projected onto the surface of the object, which is

recorded by two stereo cameras. A 3D model can be calculated from the distortion of this pattern.

The scaling is done directly during the scanning process. The Vitronic Vitus is a structured-light

scanner.

How Does the Vitronic Vitus Work?

The Vitronic Vitus consists of a scan cabin and a pedestal for the person to be scanned. In the

corners of the scan cabin, there are four sensor columns with sensor slides, on each of which are

two cameras and a projector for the structured-light.

The scan volume of the Vitronic Vitus is approx. 1 m in diameter and approx. 2 m in height.

Measuring with the Vitus takes between 10 and 14 seconds. For scanning, the person stands on the

pedestal in the cabin. It is important that the person remains still during the entire 3D scanning

process to ensure an exact measurement.

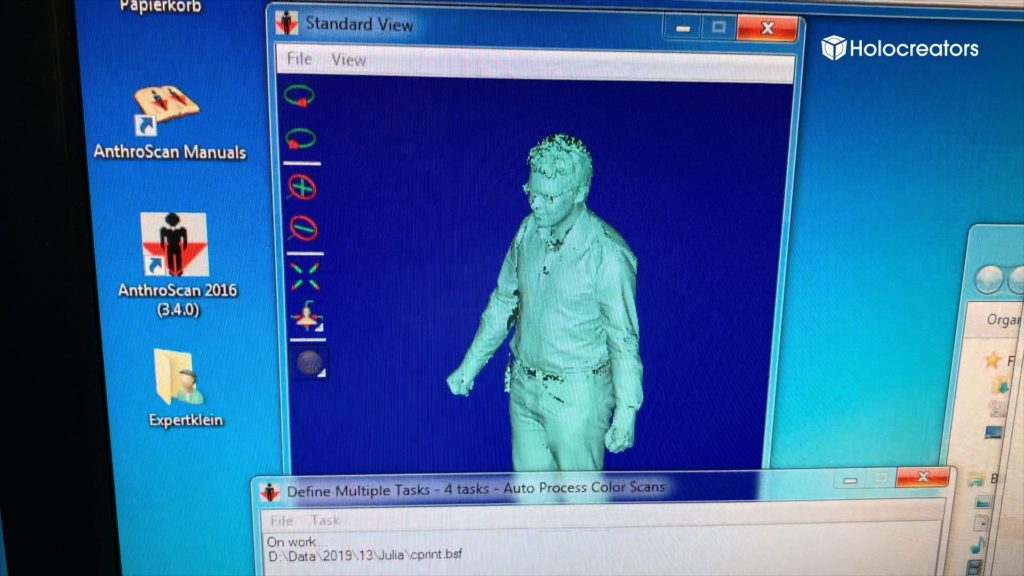

During the 3D-scanning process, the sensor slides move from top to bottom and capture the person

in 3D. An infrared light pattern is projected onto the person, which is detected by two stereo

cameras. While the sensor slides move up again, another camera captures the color information of

the person, so that a colored 3D model can be created. The total recording time, including data

processing with the Anthroscan software from Human Solutions, is about 60 seconds.

The Specifications of the Vitronic Vitus

The Vitronic Vitus body scanner weighs about 250 kg (551 lbs.) and is relatively mobile. According to

the manufacturer, the weight has been reduced since the previous model, making the device easier

to transport and set up. The 3D scanner can be taken along to trade fairs or events and can be by

two people in about four hours.

The total diameter of the 3D scanner is about 2.20 m (7’ 2”), and it’s about 2.90 m (9’ 6”) tall.

According to the manufacturer, however, a ceiling height of at least 3.10 m (10’ 2”) is required for

the assembly. The Vitronic Vitus also has its own lighting system in the scan cabin, which makes its

use independent of external lighting conditions. The list price of the Vitronic Vitus is currently

approx. 60,000 euros (70,860 USD).

Conclusion

The Vitronic Vitus is a structured-light scanner that has been optimized for body scans. It is cheaper

than a photogrammetry system with DSLR cameras. A big advantage of the Vitronic Vitus is that

directly after the 3D scan, a correctly scaled 3D model can be exported.

Do you need a person (figure) 3D scan with the Vitronic Vitus?

Holocreators offers professional 3D-scanning and reverse engineering services. We are happy to

offer you the 3D scan with the Vitronic Vitus or process your 3D scan data created with this device. Please call us at +49 40 481133 or send an email info@holocreators.com