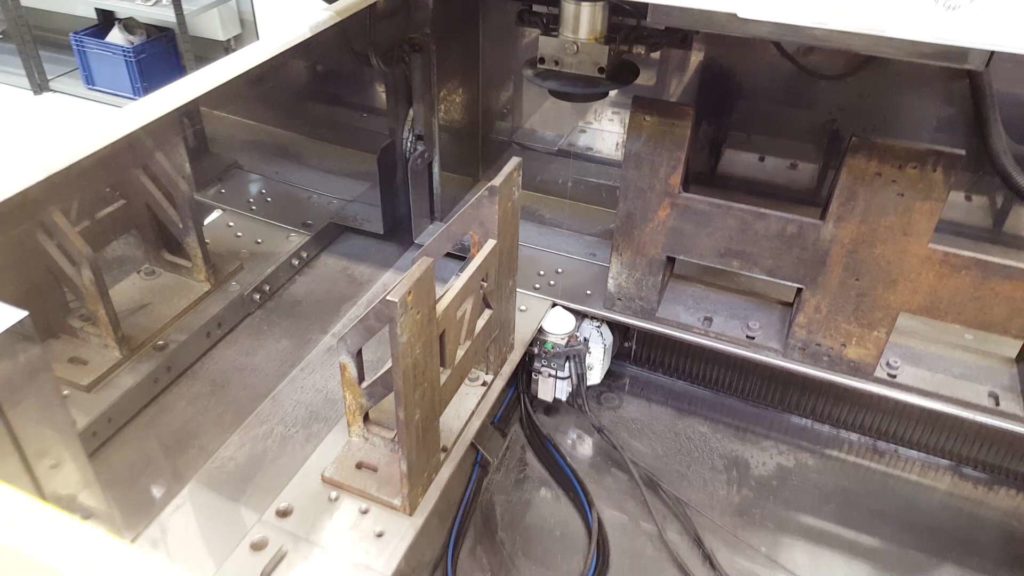

How Does Wire EDM Work?

The wire EDM machine works like a precision band saw. However, the interesting thing is that the

“saw” never touches the workpiece. The wire EDM machine has an extremely thin brass wire, the socalled “EDM wire”. This produces up to 1 million electric sparks per second. These sparks erode the

workpiece and carefully separate the 3D metal print from the base plate.

The EDM cutting process takes place in deionized water. This means that all minerals have been

filtered out so that the water no longer conducts electricity. The EDM wire is positively charged, and

the workpiece is negatively charged. The water (dielectric) isolates the electric current between the

two. When the machine is switched on, the wire is moved closer and closer to the workpiece until

the insulating ability of the dielectric (water) is no longer sufficient to insulate the electric current

between the two parts. The spark jumps over and melts and vaporizes the metal on the wire and the

workpiece. This is the reason for the beautiful, precise cut in the metal. The machine continually

feeds new wire because the wire can only be used for one cut.

Advantages of Wire EDM

Due to the thin EDM wire and electric sparks for cutting, the cut in the metal workpiece has a

diameter of only about 0.5 mm. This is much thinner than other cutting methods. Wire EDM can cut

all metals that conduct electricity, no matter how hard they are. At the Fraunhofer IAPT, for

example, they print almost exclusively in titanium, a very strong metal. Other tools would have

difficulty cutting through titanium, but with wire EDM, this is not a problem.

Disadvantages of Wire EDM

The biggest disadvantage of wire EDM is the cost and slow cutting speed. The EDM wire can only cut

through approx. 50-100 cm of metal per hour. Also, the maintenance costs, consumables and

electricity are much higher than with other cutting methods.

Conclusion

Wire EDM is the perfect cutting technique to cut through all electrically conductive metals. The cost

is high, but no other cutting method achieves similar clean cuts. In metal 3D printing, it is used to

detach the workpiece from the base plate.

Do you have a metal part that needs to be cut by wire EDM?

Holocreators offers professional 3D-scanning and reverse engineering services. We also have

extensive experience with metal 3D printing. We would love to help you with your project. Please call us at +49 40 481133 or send an email info@holocreators.com