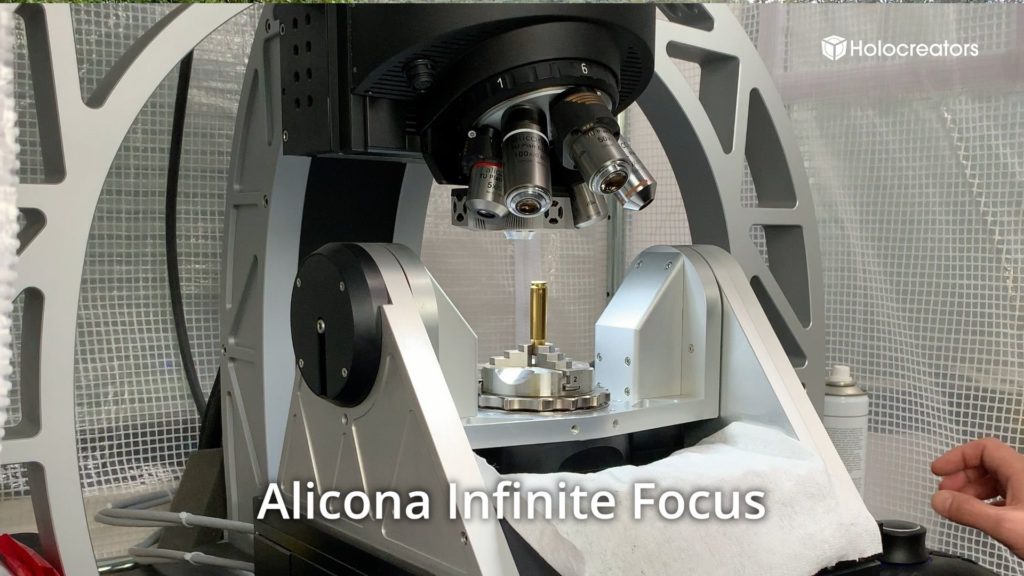

The InfiniteFocus 3D scanner from Alicona uses a very interesting 3D scanning technique: The focus

variation. By varying the focus of the camera, the 3D scanner can measure the distance to a point on

the surface of an object.

How does the Alicona InfiniteFocus 3D scanner work?

Let’s take a look at how the Alicona InfiniteFocus 3D scanner works specifically by using the cartridge

casings from our forensic ballistics experiment as an example.

The cartridge case is mounted inside the 3D scanner. The scanner is equipped with an automatically

focusing optic which focuses on a single point on the cartridge case. After the first point has been

measured, the case is moved slightly on the XY axis and the next point is selected. Compared to the

previous point, this point will likely have a slightly different Z-axis height. To bring this new point into

focus, the optic has to adjust. The height of each point is then derived from the different focus

planes. This creates the data needed for your 3D scan.

This 3D scanner is particularly good at 3D scanning small parts that have minute differences in

height, such as a coin or the back of a cartridge case.

The Live Fire Test

For our test we went to the shooting range and shot ammunition with caliber 308 Winchester from

two different rifles.

Cartridge A could be assigned to Rifle 1 and Cartridge B could be assigned to Rifle 2. A third

cartridge–Cartridge C– was fired without us knowing which rifle was used. Using 3D scanning

techniques, we were able to determine which rifle shot Cartridge C.

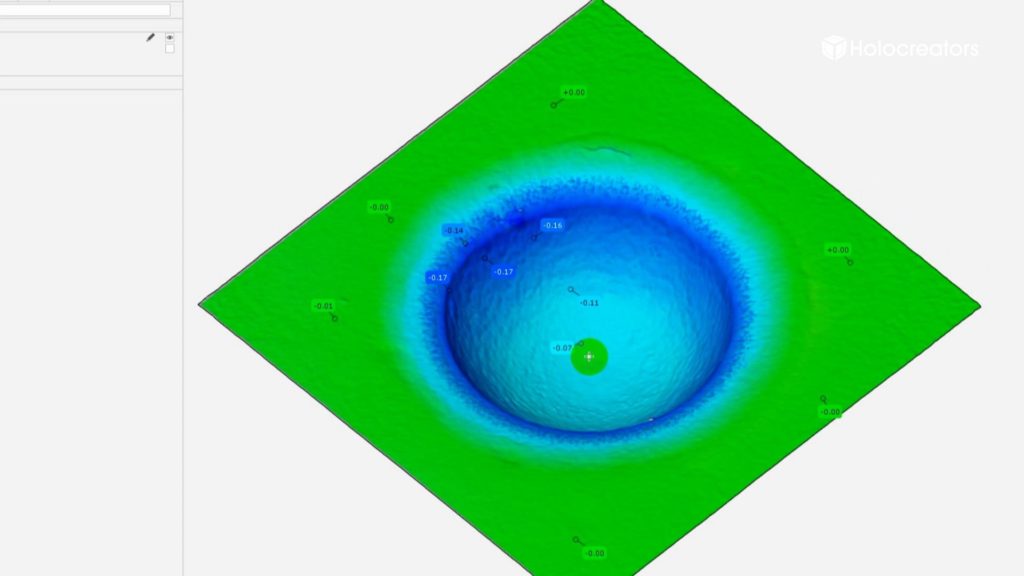

Comparing the Fired Cartridge Casings

Forensic ballistics makes use of an intrinsic characteristic of cartridge cases. When a firearm is fired,

the firing pin of the weapon leaves a very distinctive imprint on the primer of the cartridge case.

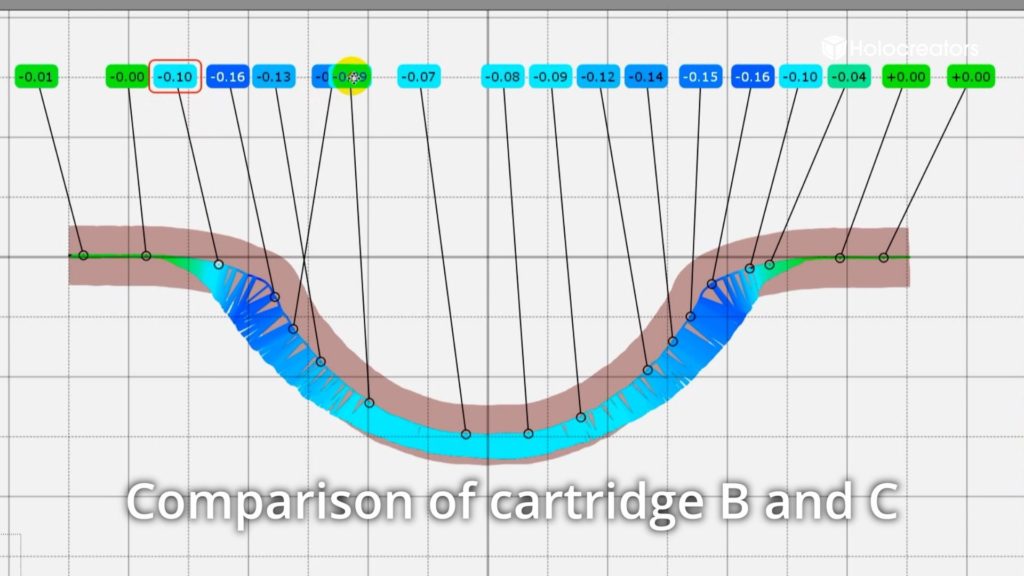

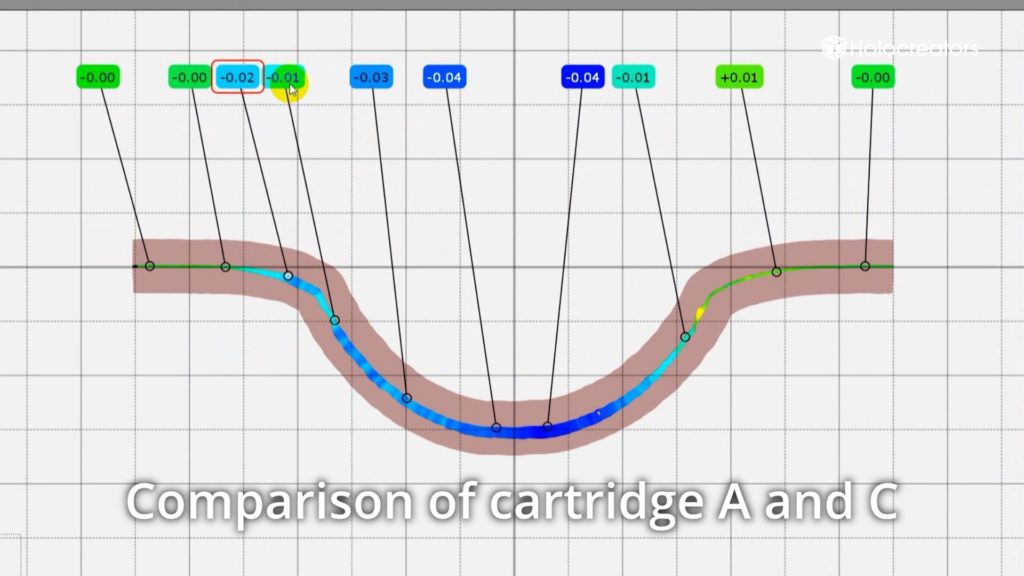

To match Cartridge C to one of the two rifles, we captured the 3D scans of all three cartridge cases

with the InfiniteFocus 3D scanner and then compared the scans inside the computer. With a

deviation analysis we could visualize and analyze the deviations between the different 3D scans.

Thanks to this deviation analysis, we can say with a high degree of probability that cartridge C was

fired from the same rifle as cartridge A. This result is further strengthened by the comparison of the

color information of the 3D scans, which the InfiniteFocus also captures. Cartridge A and C showed

the same color gradients in our test.

Download All of the Project Data

We have prepared all of the pertinent project data for you to download:

- Cartridge case A 3D scan (STL file format)

- Cartridge case B 3D scan (STL file format)

- Cartridge case C 3D scan (STL file format)

- Deviation analysis cartridge case C and A (PDF)

- Deviation analysis cartridge case C and B (PDF)

- Meshlab 3D Viewer (free Software)

Conclusion

The InfiniteFocus 3D scanner from Alicona works through focus variation. The device is perfectly

suited for making high-resolution 3D scans of small and flat objects. This 3D scanner can also record

color.

Do you need a very accurate 3D scan with the Alicona Infinite Focus?

Holocreators offers professional 3D-scanning and reverse engineering services. We also offer 3D

scanning with the InfiniteFocus 3D scanner from Alicona. We would love to help you with your

project. Please call us at +49 40 481133 or send an email info@holocreators.com